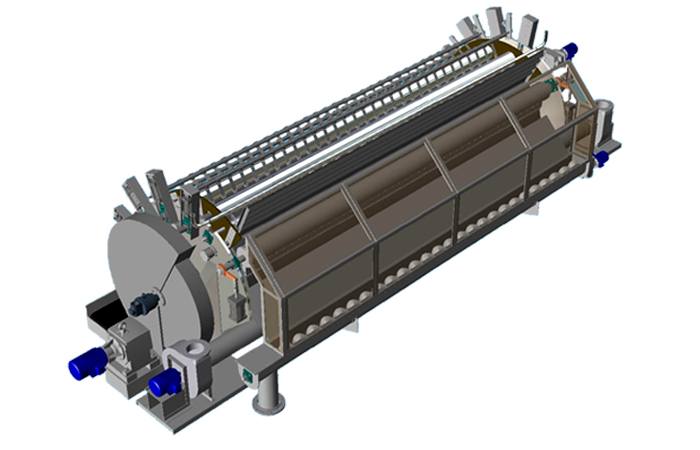

Buflovak Atmospheric Single Drum Dryer

Manufactured by Hebeler Process Solutions, USA

Single Drum Dryers utilize thin film continuous drying via conductive heat transfer with the addition of multiple applicator rolls to permit drying of successive layers of fresh material, which eliminates void areas and increases the bulk density of the final dried product.

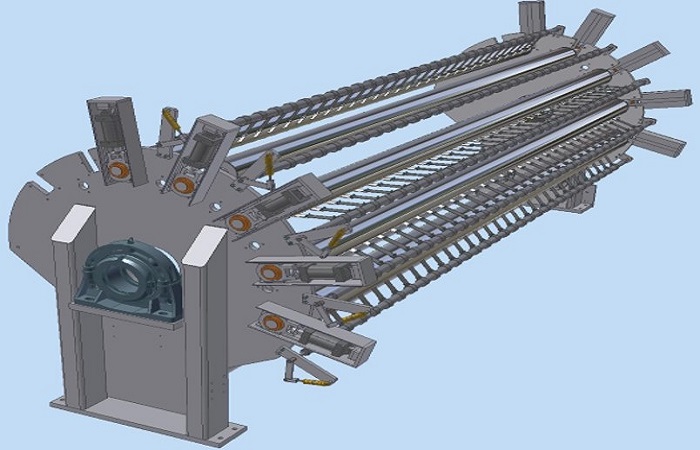

It consists of one rotating saturated steam pressurized center drum and multiple rotating, water cooled or non- cooled applicator rolls spaced around the periphery of the drum. The rotating applicator rolls eliminate void areas; permit drying between successive layers of fresh material to form the product sheet gradually resulting in a product sheet of uniform thickness, density and minimum dusting tendencies.

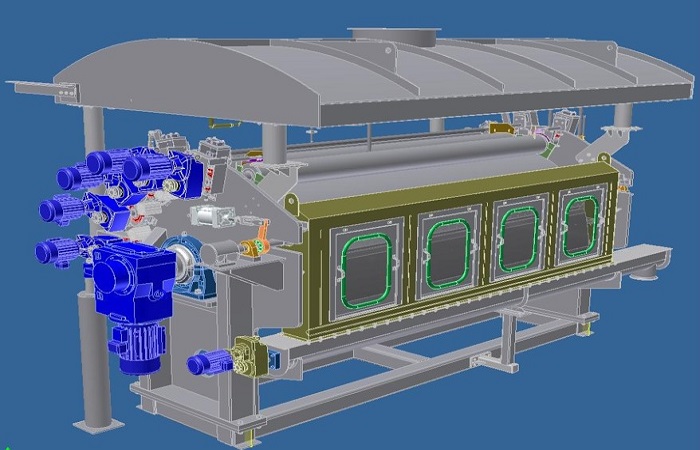

Single Drum Dryers are highly effective for drying high viscosity liquids or pasty materials such as potatoes, starches, gelatins, adhesives and synthetic resins with high drying efficiency, low operating cost and long term operational reliability.

Due to the hundreds of various types of products and operating environments, almost all aspects of a drum dryer’s mechanical design, operating components and ancillary equipment can be customized to meet each individual process design needs.